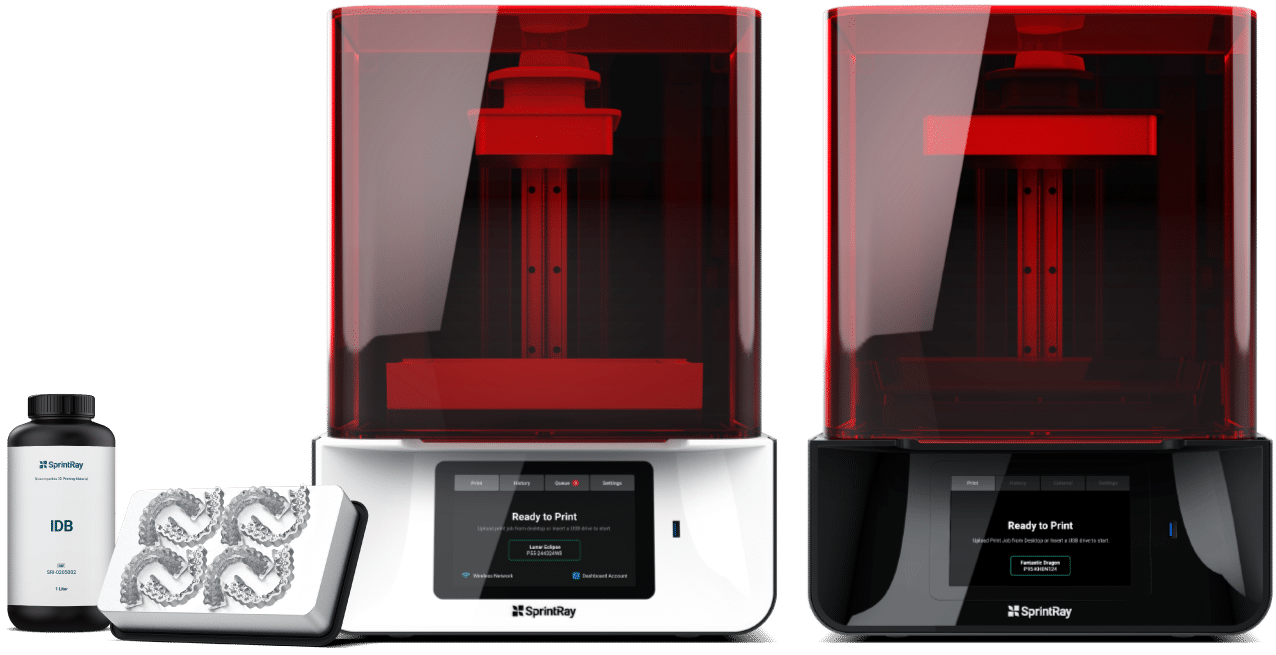

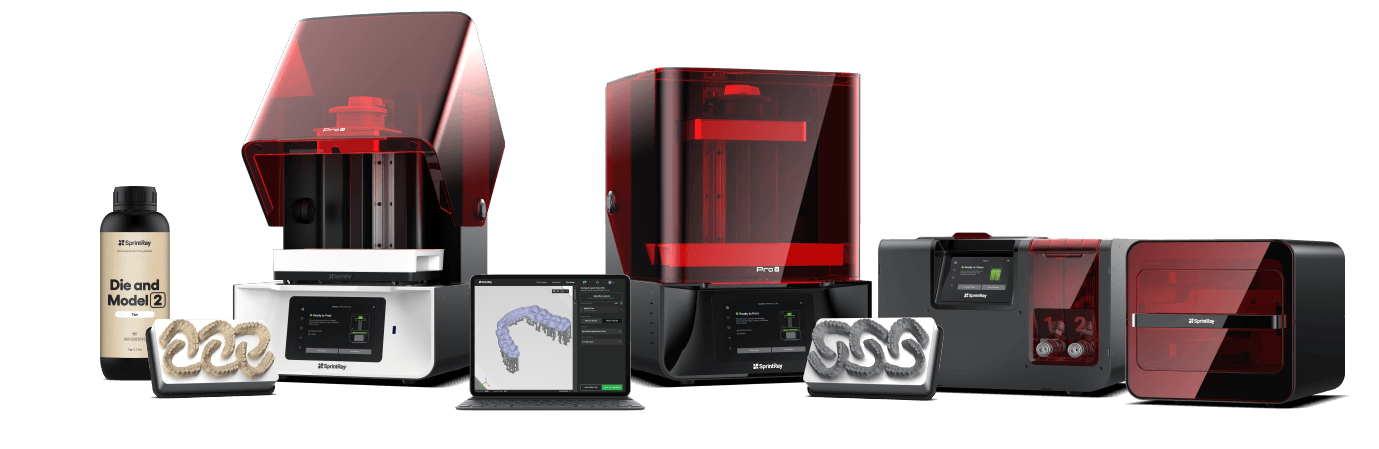

Cutting-edge Digital Dentistry Powered by SprintRay

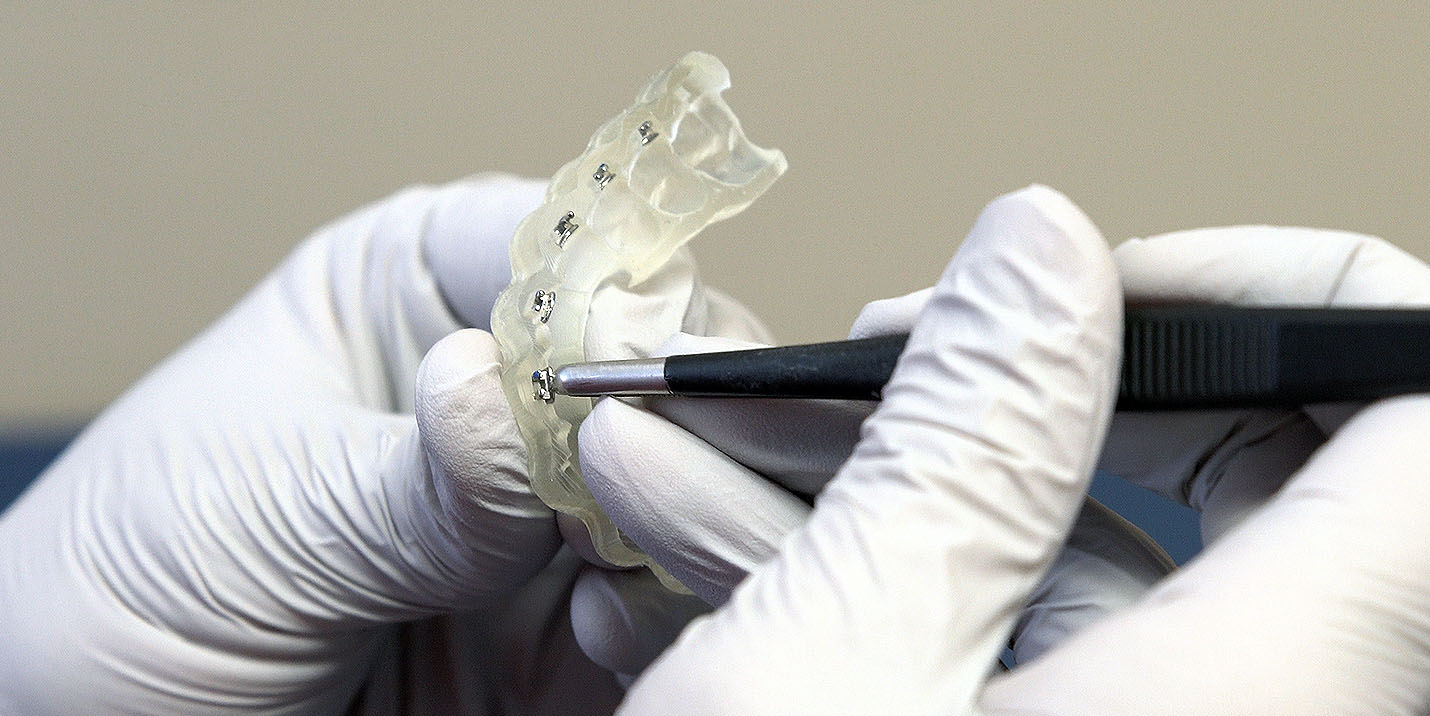

The SprintRay 3D printing ecosystem is designed for the unique needs of dental professionals. With SprintRay as your partner, pushing the boundaries of what’s possible in dentistry has never been easier.